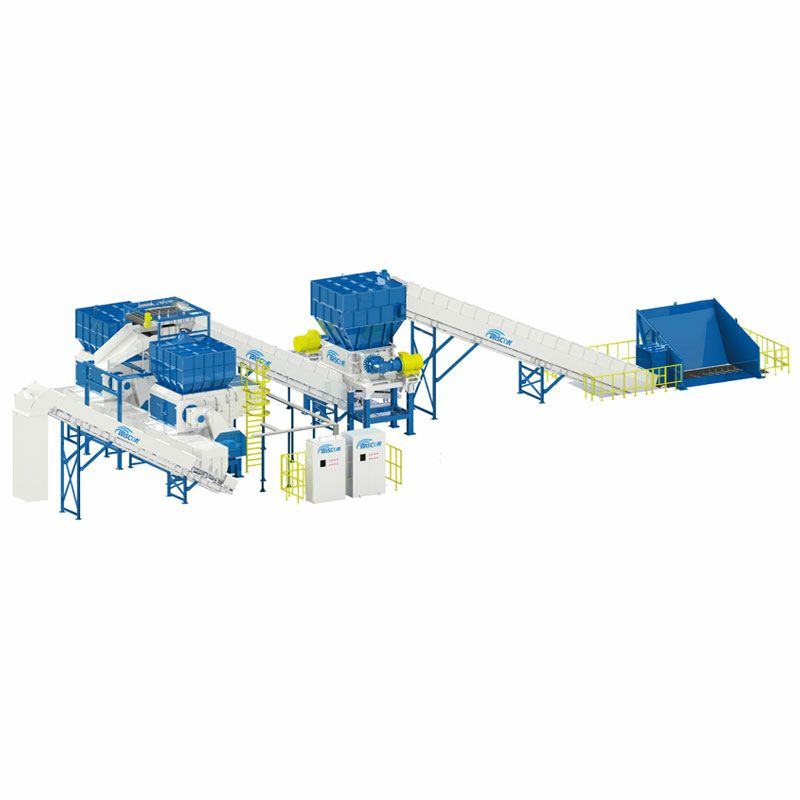

Shredder Series

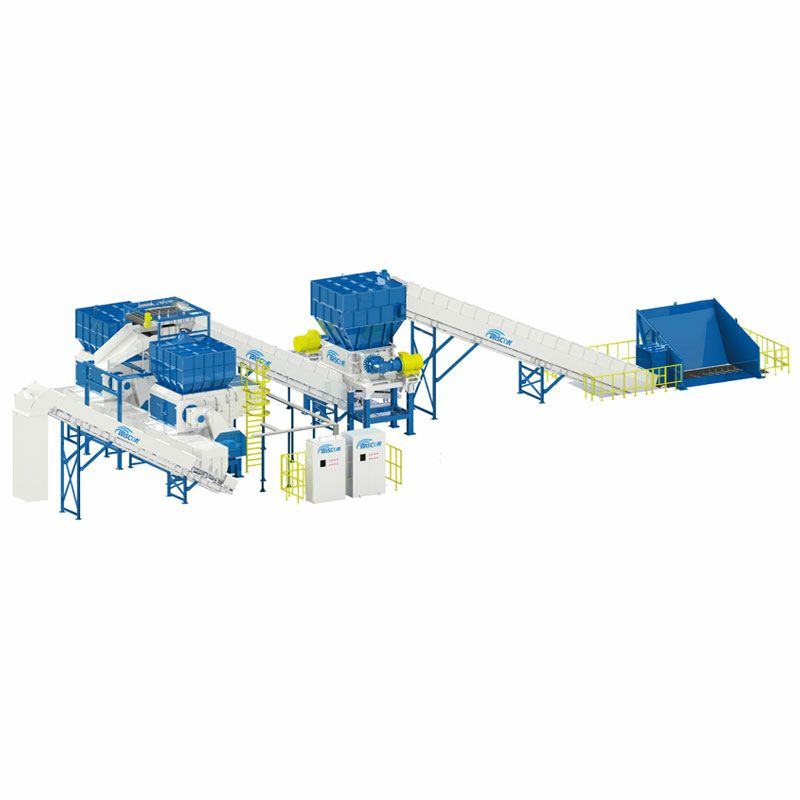

Shredder-Crusher Combined All In One Machine

CT series is a combination of shredder a...

1:In-line recycling.

2:Heavy duty, high output.

3:Process Wood and Plastics.

4:greater than 800*400mm.

Effective performance with minimal maintenance

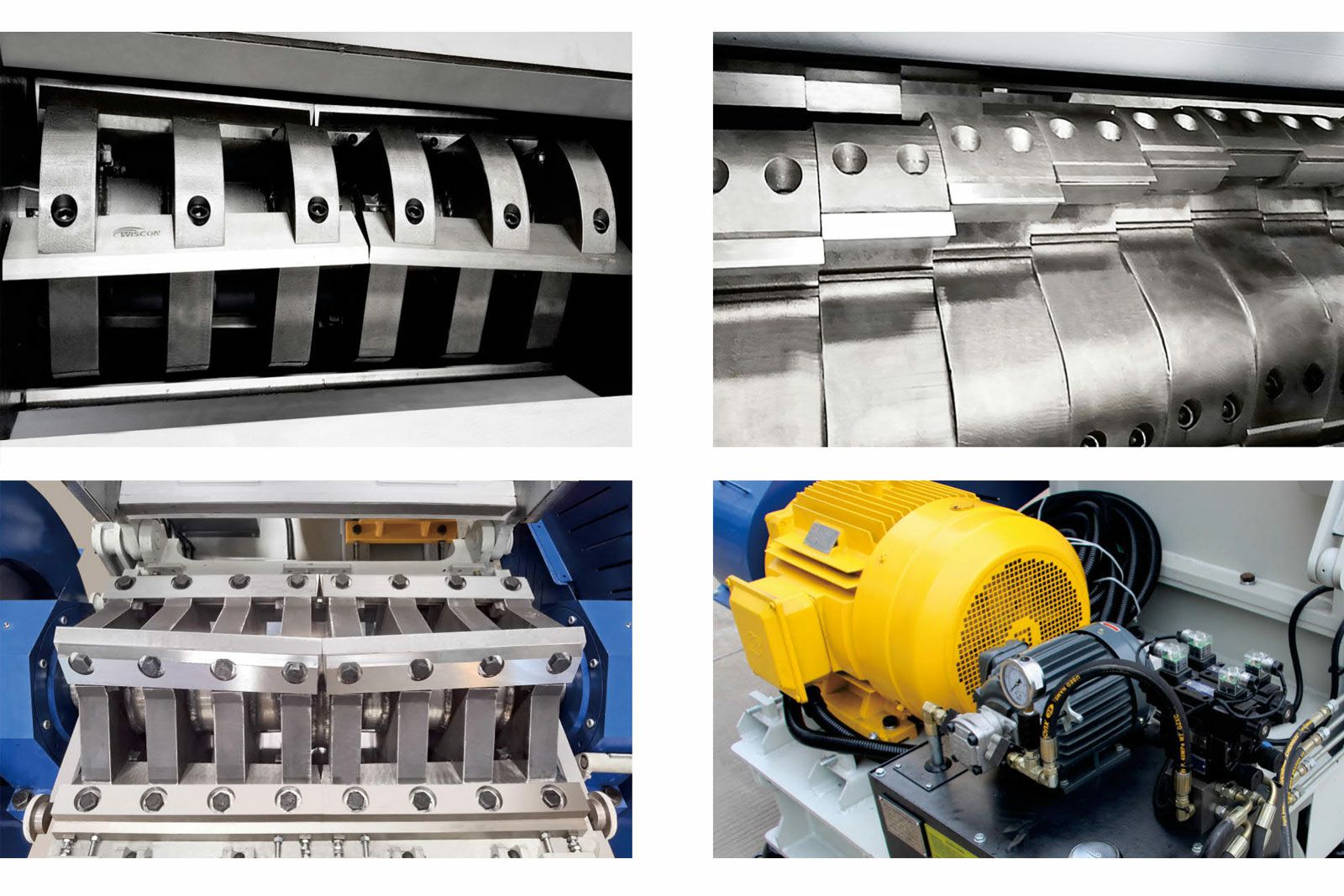

Ensures smooth size reduction of plastic and rubbery products in all sizes. The crusher is usually used as secondary shredding due to its high rotational speed and sharp blades.

Featuring robust welded steel construction and stable operation, but during crushing, metal and similar hard foreign objects are not allowed to be disposed of into crushing chamber.

The four rotors are tailored for versatile applications and producing uniform regrind, whose size is determined by screen opening.

The resulting regrind can be pneumatically conveyed and collected to form a simple recycling line with minimal dust while reducing labour cost.

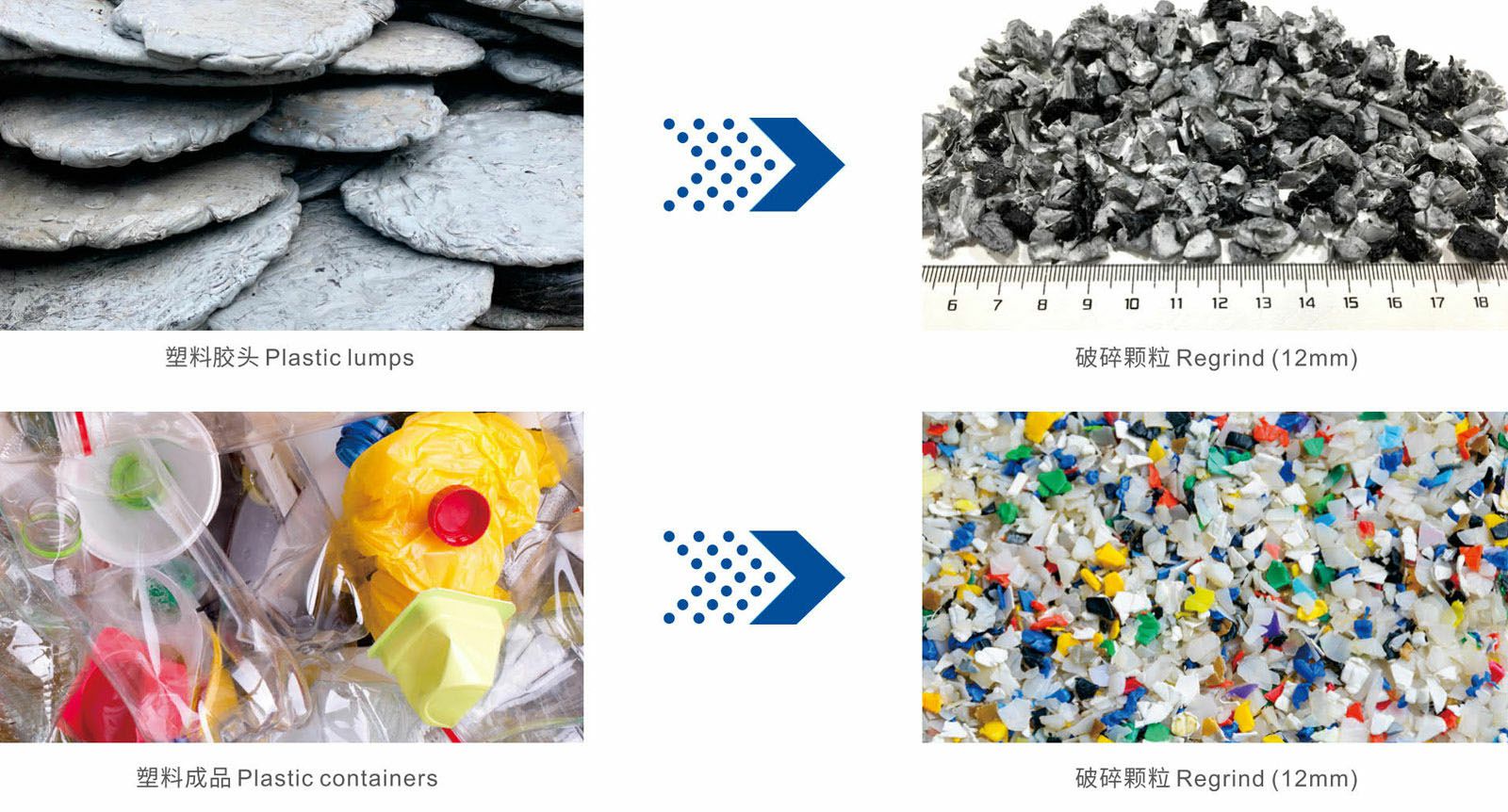

Material Showcase

Integrating a crusher with shredder and conveyor to set up a crushing system.

Applications

Plastic lump, sheet, film, pipe, bottle, sprue, runner, reject, etc.

Features

V rotor(standard), applicable for general plastic waste.

Rotary and counter knife adopts D2steel.

C rotor excels in processing tough and thick plastics.

Outbound bearing allows wet granulation.

Equips energy efficient motor and powerful hydraulic drive.

Hydraulically actuated screen cradle and hopper for easy servicing and saving 52% servicing time.

Rotary knife can be adjusted by a jig before installation.

Screen opening determines output particle size that is customizable between10-20mm.

Multiple screen options with exclusive designs for film and knitted bags.

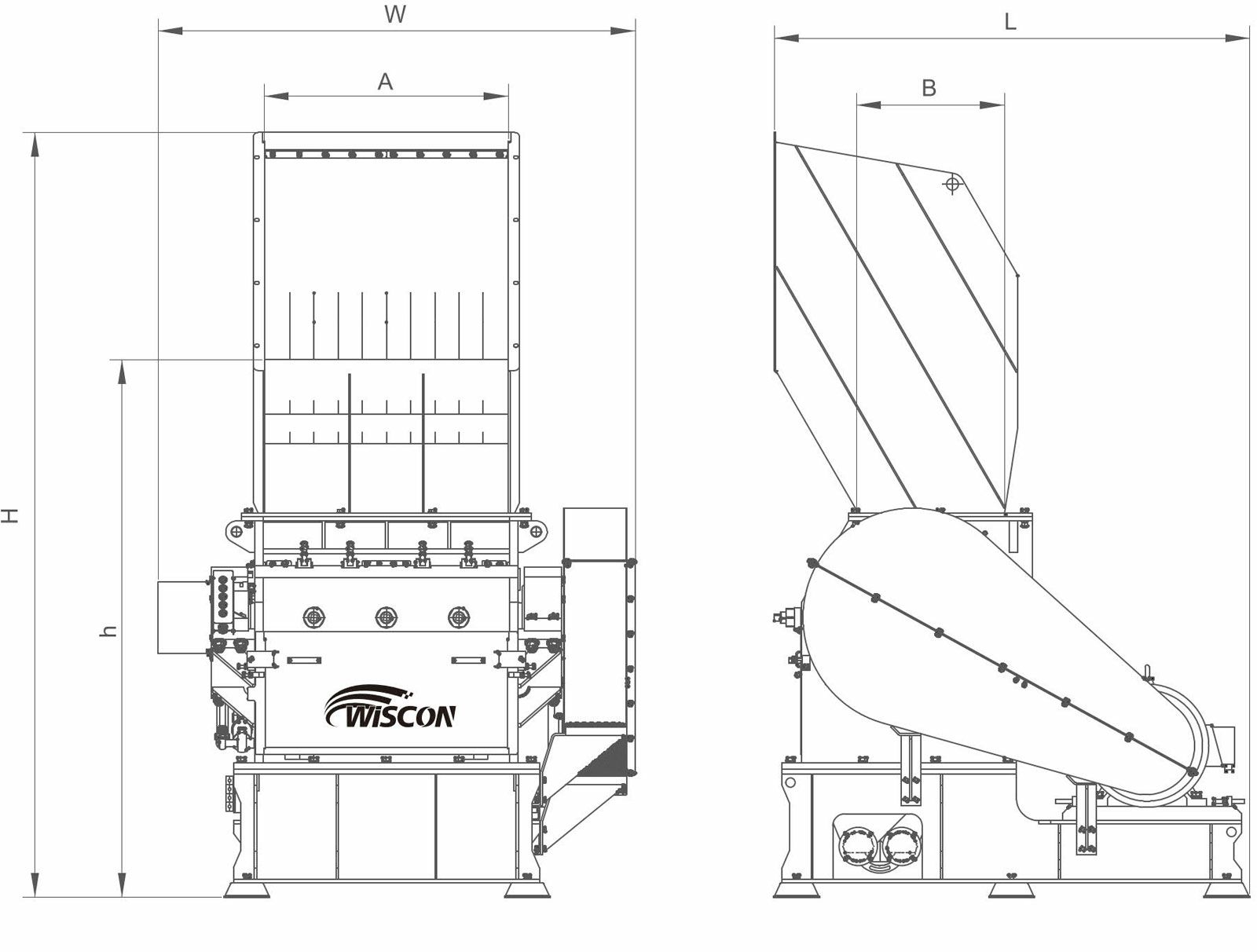

Specifications

| ltem/Model | CS360 | CS480 | CS4100 |

| Hopper opening A×B(mm) | 600×320 | 800×420 | 1000x620 |

| Rotor Diameter (mm) | 320 | 420 | 420 |

| Rotor knife qty (pcs) | 3×2 | 3×2 | 3×2 |

| Counter knife qty (pcs) | 2×1 | 2×1 | 2×2 |

| Motor power (kW) | 22 | 37 | 45 |

Dimension L×W×H(mm) | 1450×1450×2300 | 1650×1700×2400 | 1590×1863×2381 |

| Infeed Height (mm) | 1550 | 1670 | 1706 |

| Maximum output (kg/h) | 500 | 800 | 1100 |

| Weight (kg) | 2200 | 2700 | 2900 |

| ltem/Model | CL580 | CL5100 | CL5120 | CL6100 | CL6120 | CL8120 | CL8160 |

| Hopper opening A×B(mm) | 800×520 | 1000×520 | 1200×520 | 1000×660 | 1200×660 | 1200×800 | 1600×800 |

| Rotor Diameter (mm) | 500 | 500 | 500 | 600 | 600 | 800 | 800 |

| Rotor knife qty (pcs) | 5×2 | 5×2 | 5×2 | 5×2 | 5×2 | 7×2 | 7×4 |

| Counter knife qty (pcs) | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 | 3×4 |

| Motor power (kW) | 45 | 55 | 75 | 75 | 90 | 110 | 160 |

| Screen opening (mm) | Φ12 | Φ12 | Φ12 | Φ12 | Φ12 | Φ12 | Φ12 |

| Dimension L×W×H(mm) | 2000×1800×3200 | 2000×2000×3200 | 2100×2200×3200 | 2300×2100×3600 | 2300×2300×3600 | 2700×2500×3900 | 2700×2900×3900 |

| Infeed Height (mm) | 2250 | 2250 | 2250 | 2400 | 2400 | 2700 | 2700 |

| Maximum output (kg/h) | 1700 | 2000 | 2500 | 2700 | 3400 | 3500 | 4500 |

| Weight (kg) | 3850 | 4320 | 4820 | 5430 | 6860 | 10030 | 14405 |

The maximum output is tested based on plastic particles in initial size 40mm and using screen opening 12mm.

We reserve the right to change specifications without prior notice.

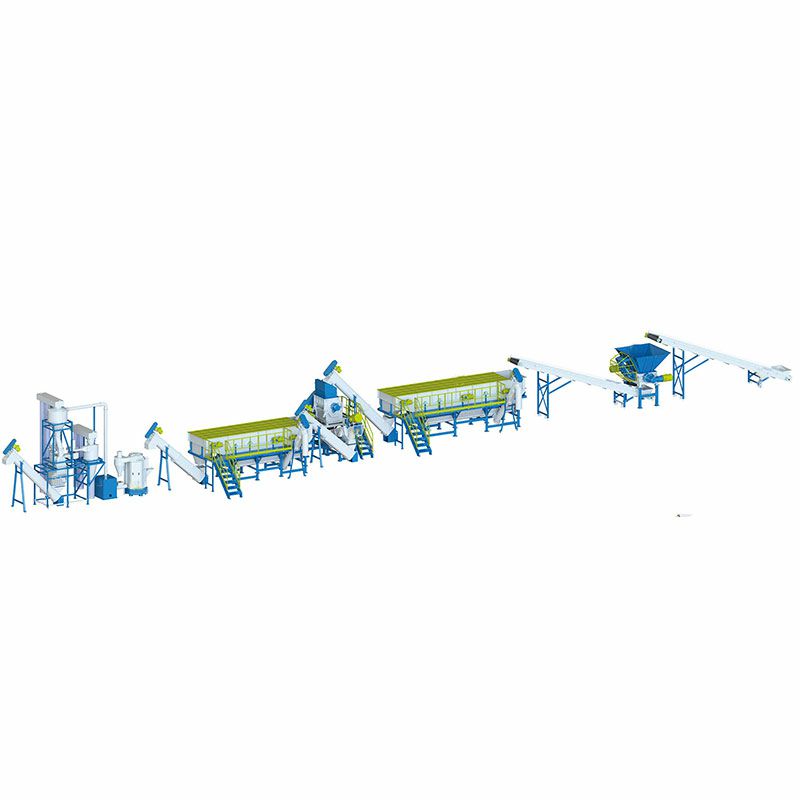

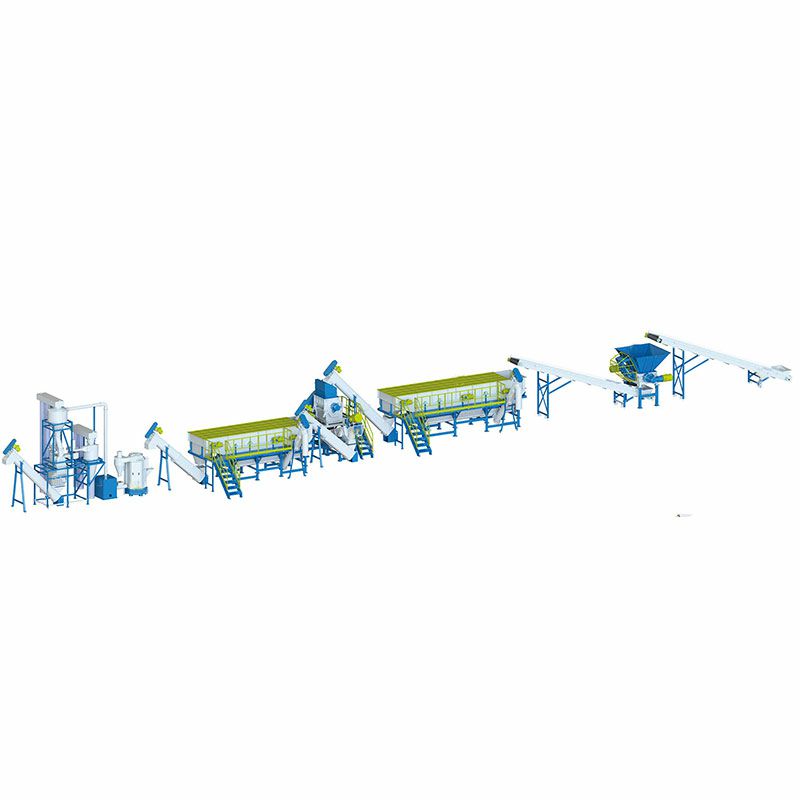

Shredder Series

CT series is a combination of shredder a...

Shredder Series

Applicable: Bulky waste, industrial wast...

Shredder Series

Applicable: Plastic film, knitted bag, a...