Shredder Series

Shredder-Crusher Combined All In One Machine

CT series is a combination of shredder a...

1:DS Series twin shaft shredder can handle a wide range of solid waste.

2:DS series has lower speed, higher torque, and higher efficiency.

3:It excels in size reducing industrial waste, MSW, electronic waste, waste household appliances and other mixed wastes.

4:Its structure is relatively compact and maintenance-friendly with a maintenance door that provides full access to the crushing chamber and bearing housing.

its shredded particle size depends on the blade thickness.

Exceptionally high torque to shred it ail

The DS series of the double shaft shredder can process a wide range of solid wastes.

Compared to single shaft shredder, this series has a lower speed, higher torque, and higher efficiency. It's mainly used to process industrial waste. Maintenance is easy and convenient since the maintenance door provides full access to the crushing chamber and bearing housing. With the shredder being screenless, it is often used for primary shredding and its output size depends on the blade thickness.

Applications

RDF(Refuse Derived Fuel): MSW, industry waste, wood, paper, tires, plastics, etc.

Metal materials: Aluminum, ferrous, non-ferrous, steel drum, waste automative, etc.

Electronics: WEEE, electronic equipment, waste household appliance, etc.

Aluminum: Can, aluminum product, building material, sheet, etc.

Plastic: Plastic drum, plastic lump, films, etc.

Features

Knives adopt alloy steel 42CrMo realizing heavy-duty size reduction.

Driving torque is evenly distributed to the shaft, thanks to splined teeth and hex shaft.

Main electrical components are sourced from trusted brands such as Siemens and Schneider.

Auto-reverse system re-orients rotor direction when motor overload & material jam.

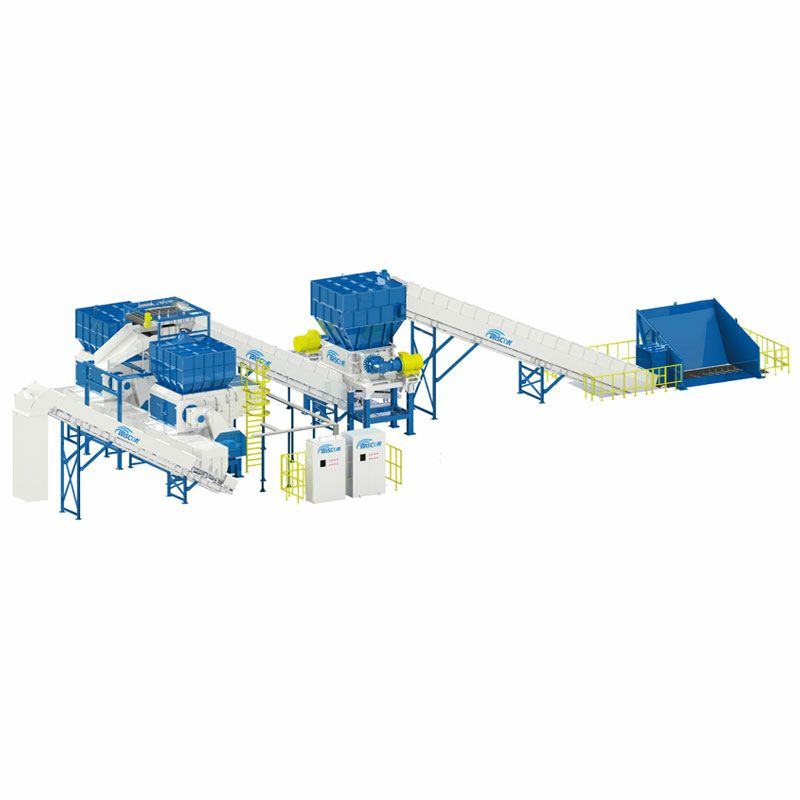

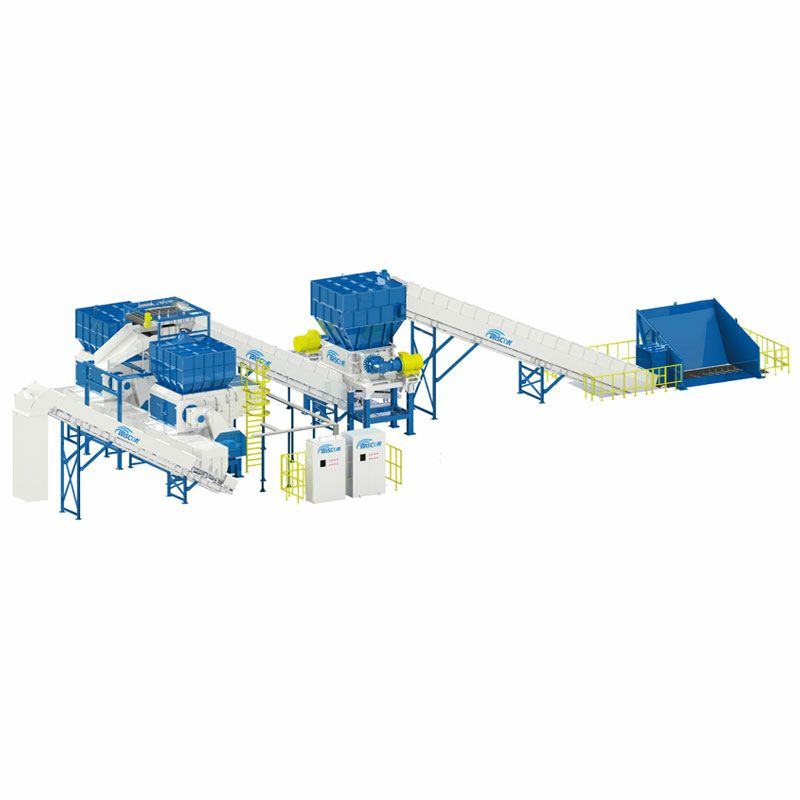

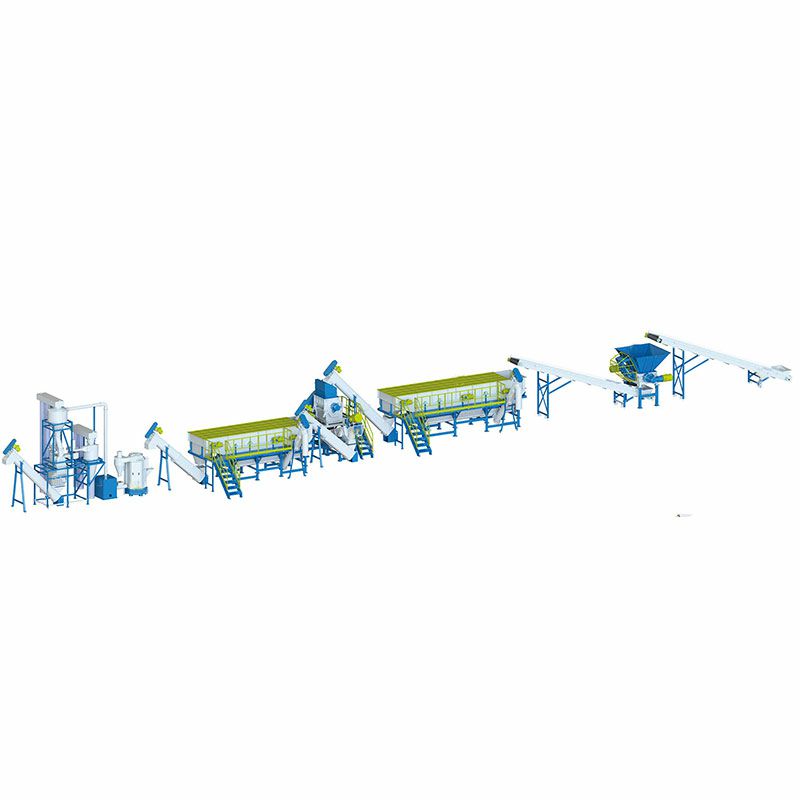

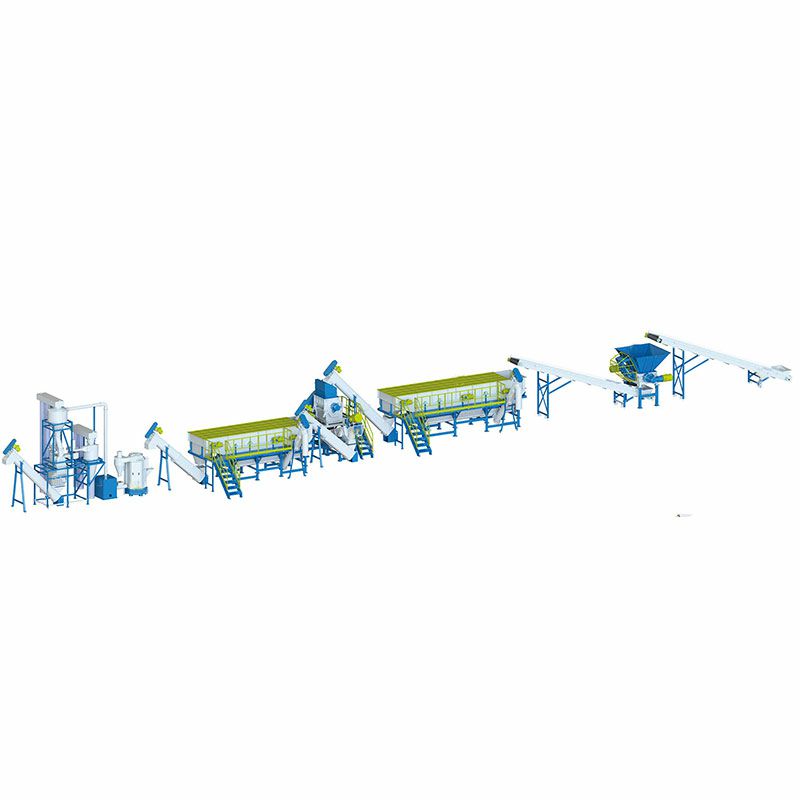

Integrating a double shaft shredder with single shaftshredder and conveyor to set up a shredding system.

Standard rotor with customizable knife thickness.

Detachable knives reduce knife replacement time significantly.

Two independent drives with gear reducers bring a high torque.

Optional to pair a vertical pusher for hollow and oversized materials.

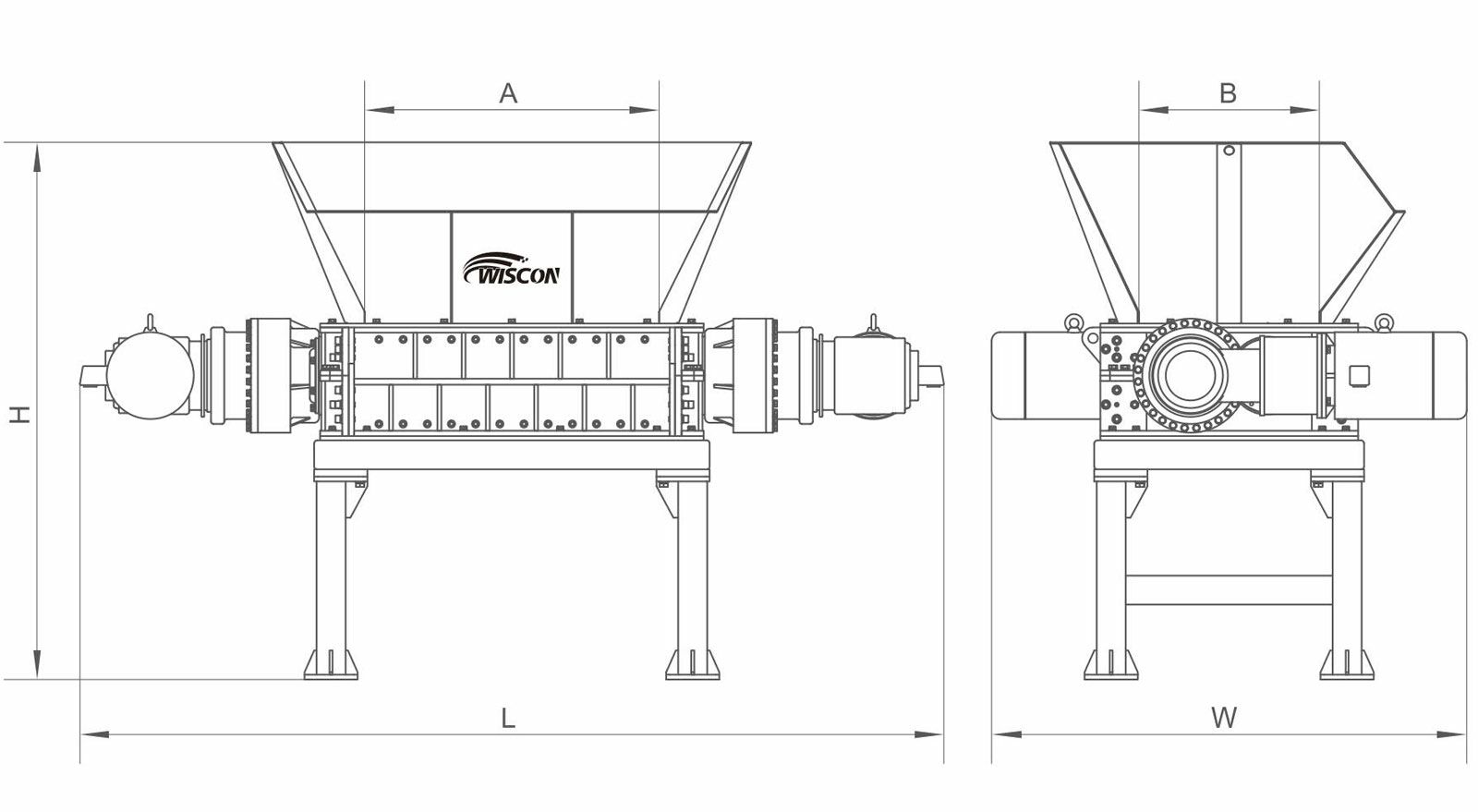

Specifications

ltem/ Model | DS260 | DS280 | DS380 | DS3120 |

| Crushing chamber A×B(mm) | 600×460 | 800×460 | 800×720 | 1200×720 |

| Rotor diameter (mm) | 300 | 300 | 430 | 430 |

| Blade thickness(mm) | 20 | 20 | 20/40 | 20/40 |

| Rotor knife qty (pcs) | 30 | 40 | 40/20 | 60/30 |

| Motor power (kW) | 5.5+5.5 | 7.5+7.5 | 15+15 | 22+22 |

| Dimension L×W×H(mm) | 2500×1180×1830 | 2740×1180×1830 | 3060×1850×2230 | 3580×1970×2230 |

| Weight(kg) | 2000 | 2250 | 4300 | 5800 |

Blade thickness and number of teeth can be selected as required.

Rotor speed and motor of DS380 and DS3120 can be customized.

We reserve the right to change specifications without prior notice.

Shredder Series

CT series is a combination of shredder a...

Shredder Series

Applicable: Bulky waste, industrial wast...

Shredder Series

Applicable: Plastic film, knitted bag, a...